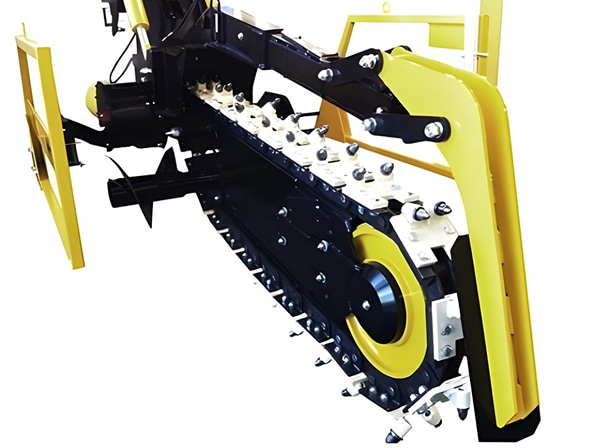

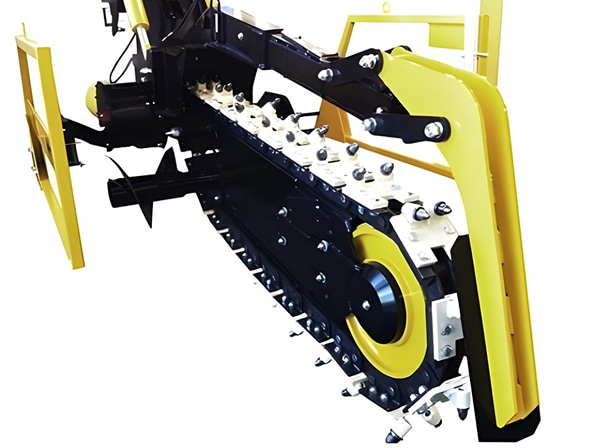

The AFT100 at a glance

- Productive trenching (typically between 75 and 150 metres per hour)*

- Ideal for fibre optic cables, CCTV cables, water pipes, drainage and more

- A fraction of the cost versus a self-propelled trencher

- Bullet chain available for extra tough conditions

- A clean-cut trench

- Easy backfilling with finely cut spoils left on each side of the trench (a simple blade on your tractor can be used to backfill)

- The modest weight of the trencher (1400-1900kg depending on accessories) allows it to be operated using a 100+ HP tractor

*Speed will depend on various factors such as ground conditions and depth/width of the trench.

The AFT100 for civil contractors in action

Formosa Fencing completing 10km of CCTV infrastructure in a solar park

MJ Wilson Contracting using the bullet

chain to dig in extra tough conditions

Main Features & Components

- Maximum Depth: 1.0, 1.2, 1.4, 1.6 or 1.8m

- Trench width:

- Standard Chain:

- Optional welded bullet chain for extra tough digging conditions:

- Soil augers (to leave the finely cut spoils at the sides of the trench)

- Weight: 1,400kg – 1,900kg (depending on accessories)

Tractor Requirements

- 100+ HP with CAT 2/3 linkage

- Vario transmission OR Creeper gearbox (with a minimum speed of 50-100 metres/hour)

- 1-3 sets of feed/return spool valves depending on trencher accessory choices

- PTO shaft 6 spline, 540 RPM

You will need at least a 100 HP tractor

(ideally 120/140 HP +) to operate the AFT100

Why choose the AFT100?

What civil contractors say about the AFT100

“With a digging bucket, I would need at least a day to dig 300 metres. With the AFT100 trencher, I can do it in one hour”

Tony Elliot

Tugwell Contracting, Civil Contractor

“Impressed with the speed of the trencher and the cleanliness of the trench, the team behind were struggling to keep up to lay ducting!”

Richard Formosa

Formosa Fencing, Civil Contractor

Frequently Asked Questions

Can the AFT100 go on any tractor?

The AFT100 requires a 100+ HP tractor with vario transmission or a creeper gearbox (with a minimum speed of 50 to 100 metres per hour).

Is the AFT100 easy to maintain?

Yes, other than checking the gearbox oil level, checking and adjusting the chain tension and greasing appropriately, the AFT100 is very easy to maintain.

How long will the chain last?

AFT uses chains and blades made for us in Germany. We have used the same manufacturer for over 30 years because of their quality and reliability. The wear on chains and blades depends on:

• Soil conditions (sand, clay, small rocks, etc.),

• Tractor speed,

• Depth and width of the trench.

We would be pleased to discuss in more detail your specific trenching conditions.

How will the standard chain cope with stones or clay?

The AFT100 has been designed to cope with various ground conditions, including stones (the size of footballs), heavy clay, sand and even asphalt.

What can you suggest for compacted ground or rocky soils?

We have the heavy duty AFT100 fitted with a bullet chain.

Do you have second-hand machines available?

Yes, we sometimes do. Please contact us to find out.

What is the typical speed of trenching?

Depending on soil conditions and the depth and width of the trench, anything from 75 to 150 metres per hour in normal conditions, in stony ground, slower, and in sandy conditions, faster.

Is there a safety mechanism for the gearbox?

We have an inbuilt clutch within the PTO shaft to protect against damage.

Where are the machines manufactured?

Our machines are manufactured at our factory in Sudbury, Suffolk, UK.

English

English Français

Français Deutsch

Deutsch español

español Italiano

Italiano 日本語

日本語 Eλληνικά

Eλληνικά русский

русский